Schedule a Call Back

Mini Machines, Mega Impact

India’s construction industry is undergoing a dynamic transformation—driven by ambitious government schemes, urban renewal efforts, and rural infrastructure development. At the heart of this evolution lies a powerful enabler: mini construction equipment. Compact, efficient and investment friendly, these machines are redefining how small-to-medium infrastructure projects are executed across the country.

Meeting India’s infra needs

As cities grow denser and villages demand better connectivity, the need for agile and efficient construction solutions has soared. Mini construction equipment such as walk-behind rollers, plate compactors, concrete vibrating pokers, and concrete cutters have become indispensable across both urban and rural job sites. The surge in demand is especially visible in projects supported by flagship programmes like PM Gati Shakti, Smart Cities Mission, PMGSY, and PMAY-Urban.

Market indicators tell the story that equipment like mini excavators (under 3 tonne) and concrete/asphalt cutters have seen significant growth year over year, highlighting their increasing relevance in everything from utility trenching to precision paving.

Light equipment thrives in environments where traditional machines struggle. Whether it’s a small walkway in the gardens or compacting the bunds at small irrigation sites or compacting the basements in multi-storeyed buildings, their compact size and application relevance makes them perfect for navigating limited-access areas. These machines are less noisy, designed to operate with special considerations minimising disruption in hospitals, schools, and residential zones even during daylight hours.

Their mobility and ease of transport allow for quick relocation between job sites to make them the best choice for investing in them. According to NHAI studies, urban projects using mini machines report lesser traffic disruptions, a crucial factor in public-facing works.

Alongside, Indian market is changing to more scientific way of doing construction projects instead of traditional methods. This also reduces the risk with dependency of skilled labour.

Designing for India

Light equipment built for the Indian market must endure rugged conditions, high heat, and varying fuel quality. We have responded well by developing models that offer:

- Fuel efficient by using well-known and reliable engines

- Durability in extreme temperatures

- Simplified design for easy maintenance using locally available parts

- Affordable price points

- Short time training programmes from few hours to less than two days to improve the skill of operators

These characteristics are not just desirable—they are essential to ensure successful adoption in India’s continuously evolving and skill-constrained construction ecosystem.

Time is money

Mini equipment significantly shortens project timelines. A single walk-behind roller can compact larger areas compared to manual methods. One mini machine can minimise too many labour interventions, resulting in productivity gains. These machines also improve material utilisation and finish quality there by achieving better consistency and longer life of constructions. From housing projects under government initiatives to infrastructure developments, mini equipment plays a critical role in ensuring speed, quality, and consistency.

Contractors and operators are embracing the change

As awareness spreads, adoption is accelerating especially in tier-2 and tier-3 cities. We have plans to improve adoption by engaging with partners who helps us develop operator ecosystem under Skill India Mission. Small and midsize contractors are increasingly diversifying into rental models of doing business.

Looking ahead

Dynapac is aware of opportunities, and we have been proactive in building our light equipment portfolio at Dynapac factory in Pune to cater for domestic and international needs. In India, we operate the light compaction portfolio under Redline Brand to meet the domestic needs of the product. We offer a full range portfolio of both compact and concrete products which places us well to offer the right products for the application.

ABOUT THE AUTHOR:

The article is authored by Mahesh Grampurohit of Dynapac.

Subscribe Now

Subscribe to our Newsletter & Stay updated

RECENT POSTS

Popular Tags

Folliow us

Related Stories

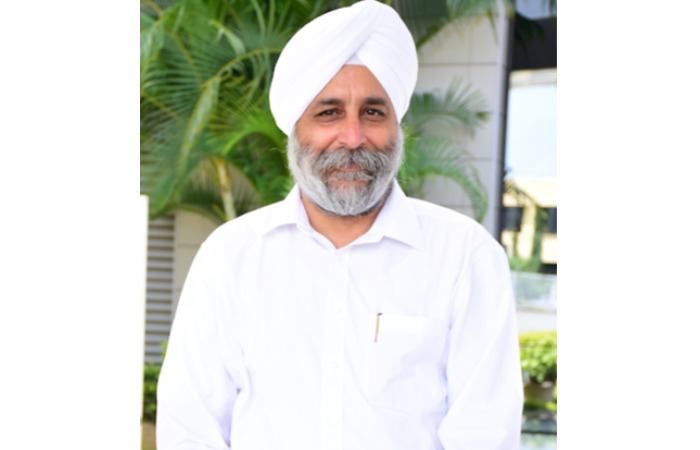

Paramjit Singh Chadha named MD of ZF CV Control Systems India.

ZF Commercial Vehicle Control Systems India Limited has announced the joining of Paramjit Singh Chadha as its new Managing Director. Paramjit bri...

MoRTH to Frame IRC Norms for New-Age Machines in Highway Work

The Ministry of Road Transport and Highways (MoRTH) has decided to formally adopt Automated and Intelligent Machine-aided Construction (AIMC) for...

We are among the global top 3 in tech adoption

As energy gains global importance, L&T has built a strong presence across hydrocarbons, power, renewables and green technologies. With energy...