Tags :

Schedule a Call Back

The cost curve in the Indian cement industry has been on an upward trajectory. ICR delves into the causes behind it and its impact while endeavouring to answer the important question – how much of this is permanent?

If the financial year 2022 was the year of shipping costs soaring to the highest level, the financial year 2023 started with the coal and pet coke prices moving to the stratosphere in tandem, largely buoyed by the geo-political headwinds with the war in Ukraine, forcing a sanction of a large part of the oil, gas and coal from the Russian sources to the Western world. The fallout of this was a steep hardening of the coal futures, both New Castle and API4 Indexes shot up to the extreme levels it has never seen in the past. While these

were FOB prices, the shipping freight, albeit softening from the stratospheric levels, were still high by any standard.

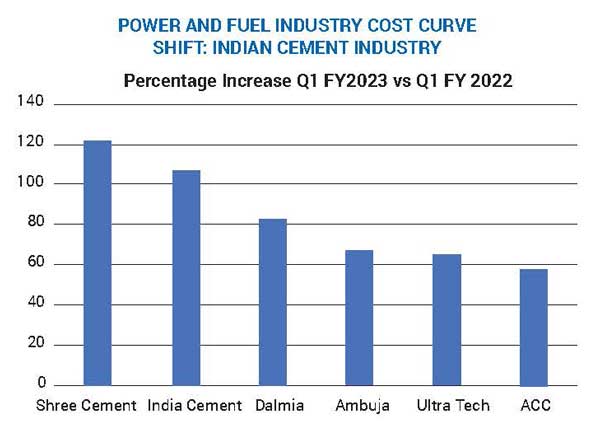

The Indian cement industry was hugely impacted by the rise in power and fuel prices as this contributes to 30 per cent of the industry cost of producing and distributing cement, the logistics cost still remaining high at 40 per cent of the total costs. The first quarter of FY2023 saw an across the industry rise of above 60 per cent in the power and fuel cost as attached in the graph below (compiled from the quarterly reports of the key industry players).

Market Dynamics

This rise has however cooled down in the recent quarter, but a large part of the rise seems to be permanent and the total shift in the industry cost curve is expected to be 20 per cent higher on power and fuel cost together with the impact of logistics cost. How do we explain this structural shift in cost?

While most of the analysis is based on the spot prices of coal, both in the international and domestic market, which in turn influences the prices of pet coke as well, the private buyers of coal and pet coke do not trade on spot basis for the bulk of their portfolio, which is built on an optimised model for buying a mix of domestic coal (linkage auction, e-auction and market coal), imported coal (RB1,2,3, Indonesian, other sources, etc), domestic pet coke (Nyara, Reliance, IOCL, etc), imported pet coke (U.S. East Coast, Oman, LATAM, etc), such that the landed cost could be minimised on the basis of rupee per kcal (heat value) as the portfolio must be normalised over the range of GCV options.

Private sellers and buyers have experienced in their own way through tenured contracts that inter-dependence in a highly volatile market did demonstrate better results over the long run, but in the short term both sides have engaged in short term opportunism. This has put additional strains in the system and these postures have influenced the spot prices. While the FOB prices started to show distinct ‘out of bound’ movement, the shipping costs remained high throughout this period and only recently have shown a definitive downward trend.

The individual cement players within the industry have very different portfolio of their own, built through the years on an optimisation programme that takes into account the kiln characteristics as well, in accepting a mix of coal or/and pet coke from a myriad of sources, where logistics cost becomes a very dominant factor; with shipping costs soaring, the negative results have been more pronounced for those who have an over-exposure to importation.

One of the important points to be noted is that the Indian coal prices have also gone up by 75 per cent on an average across a range of grades, those who have long term auction linkages still alive, are the outliers benefitting the most. The future direction of the domestic coal prices does not seem to portray a large change as most of the mines have a rising cost to contend with, as stripping ratios continue to rise every year, followed by logistics cost.

Taking on Challenges

The question of power and fuel cost rise should be seen in the long term rather than in the short term, although finding the most optimised mix in terms of cost has remained the area of focus all along. Two of the biggest challenges that urgently require solutions from the industry are as follows:

– Procyon Mukherjee

Subscribe to our Newsletter & Stay updated

Holcim has agreed to sell its Russian business to its local management. When the transaction is completed, the business will continue to operate u...

ACC Limited has won the National Award for Safety Excellence (FY2021-22) at the 10th Global Safety Summit (GSS) in the Large Enterprise-Cement Man...

ThyssenKrupp Polysius’ Asia Pacific division has secured an order for two Polflame-type main burners for an unnamed cement plant. The equipment ...